Processing Capabilities

CAD-CAM

→ Computer Aided Design (CAD) – PRO ENGINEER, CATIA V5

→ Computer Aided Manufacturing (CAM) – PRO ENGINEER, CATIA V5, TOPS 300 for NC milling machines and for combined punching and laser cutting with Trumpf machine

WELDING

→ Electrical welding

→ Welding in protective gases TIG, WIG, MAG

→ Oxyacetylene surface welding

→ Spot welding

→ Brazing

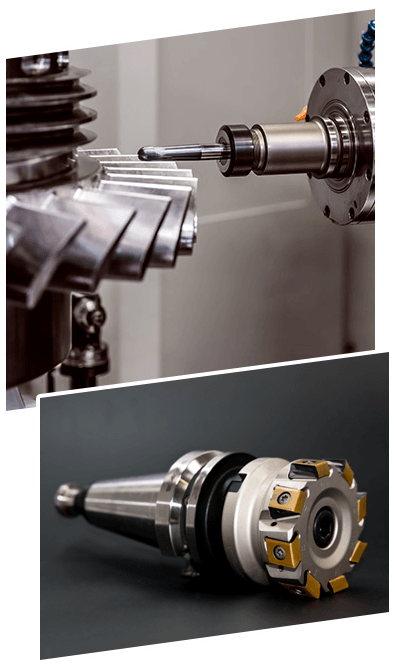

TURNING

→ Steel and non-ferrous universal turning processing for parts with dimensions: Dmax = 800 mm, Lmax = 4000 mm, precision class = IT 9

| UNIVERSAL TURNING LATHES | |

|---|---|

| SN 400 X 1000 | max. diameter of turning parts: Ø 400 mm max. distance between centers: 1000 mm |

| SNB 400 X 750 | max. diameter of turning parts: Ø 400 mm max. distance between centers: 750 mm |

| PRECISION TURNING LATHES | |

| IA 616 | max. diameter of turning parts: Ø 900 mm max. distance between centers: 750 mm |

| SV18 RA | max. diameter of turning parts: Ø 200 mm max. distance between centers: 1500 mm |

| IJ 611 P | max. diameter of turning parts: Ø 130 mm max. distance between centers: 500 mm |

→ Steel and non-ferrous automatically turning processing for parts with dimensions: Dmax = 42 mm, Lmax = 60 mm, precision class = IT 8

THREADING

→ Exterior rolling threading: Dmax = 80 mm, pas max = 4 mm, precision class IT 4

STEEL AND NON-FERROUS MACHINING ON SCHAUBLIN 6 TMY MACHINE (8 AXES)

→ Dmax = 42 mm (automatically feed), Dmax = 170 mm (piece by piece feeding), Lmax = 700 mm